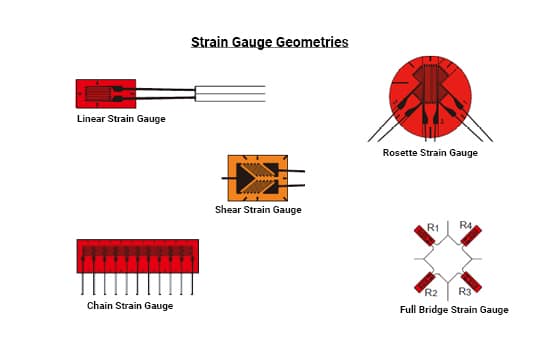

Strain measurement on a structure relies heavily on its geometry, i.e. the number of grids and the positioning of grids. To get an accurate measure of strain in a structure, the strain gauge must be mounted in the direction of the main force, which is different for different applications. For instance, a rotating structure would require different strain measurement parameters than a bending beam. For such distinct measurement requirements, there are different varieties of electrical strain gauge available in the market today. These various design patterns are designed for widely differing applications from experimental stress analysis to durability testing through transducer manufacturing.

In this article, we are going to discuss those varieties of strain gauge geometries that are developed due to stress exerted in different directions.

Linear Strain Gauge

A linear strain gauge is used to record strain in the direction in which its measuring grid is aligned. It is typically mounted in the direction of the main force, for which the direction of the force must be known. This geometry of strain gauge is preferred when measurements are to be performed in one direction only. For instance, in applications such as aircraft component testing, medical device and equipment manufacturing, linear strain gauges can be positioned to measure bending, axial and torsion strain. The linear strain gauge pattern can also be used in S-Beam, binocular, reverse bending and dual beam load cell and pressure transducer designs.

A double-linear strain gauge is an enhanced version of a linear strain gauge with two linear measuring grids arranged parallel to each other. This type of configuration is mainly designed for applications where double-sided strain measurements are required, for instance, to record the bending load of a bending beam. During such measurements, four active strain gauges are used in the Wheatstone bridge circuit.

Shear Strain Gauge

A shear strain gauge consists of two measuring grids arranged at an angle of 45° to the strain gauge axis and 90° to each other. It is mainly used to measure torque in a rotating object that includes measurements on torsion bars and determining shear stresses as they occur in shear beams in the area of neutral fibres. They are used in the construction of torque transducers or shear force transducers.

Rosette Strain Gauge

Rosettes with 2 and 3 measuring grids are widely used in various applications. A T-rosette strain gauge has two measuring grids arranged on a carrier perpendicular to each other, whereas the 3-grid geometry has 3 measuring grids spaced at different angles. These multiple strain gauge configurations are suitable for applications where biaxial stress state is to be determined with unknown principle directions based on magnitude and direction. Using a rosette strain gauge allows for different directional strain measurements which provides a more accurate evaluation of the surface strain to be measured. It is mainly preferred for strain measurement in tensile or compression bars.

Chain Strain Gauge

A strain gauge chain consists of a series of 10-15 very small evenly spaced grids sharing the same carrier. This type of configuration is ideal for measuring strain gradient i.e., the stress curve over a specific section or the shift in the peak value due to the impact of load being introduced at a moving point. The design of chain strain gauges includes measuring grid in parallel or perpendicular direction to the longitudinal chain axis.

Full-bridge Strain Gauge

A full-bridge strain gauge is composed of four measurement grids that are switched to a Wheatstone full bridge. Each measuring grid is offset to the next grid at an angle of 90°. Its common applications include measurements on torsion bars, tension or compression bars and shear stresses occurring in shear beams around the neutral fibre. The full-bridge strain gauges are also designed to manufacture precision force transducers which employ bending beam working principle.

To know more about our range of strain gauges, contact us.