Bridges and transportation infrastructure are subjected to extreme environmental loading conditions, such as snow, rain, storm, and extreme heat, which makes building materials like steel and concrete more susceptible to cracks and failures. Additionally, the possibility of physical impacts induced by vehicle traffic, overloading, and collisions with moving trucks also contributes to aging and degeneration. These could harm the ability of these structures to support loads.

Therefore, it is crucial that the bridge is frequently inspected and assessed to guarantee its structural integrity throughout its lifespan. Evaluating the bridge’s condition is based on certain metrics and subsequent evaluations. Sensors are used to measure these parameters and offer a more reliable observation than visual observation, mainly concentrating on easily visible bridge components.

Bridge Structural Health Monitoring

Structural health monitoring in bridge engineering is the technique used to evaluate the overall condition of bridges by using a network of intelligent sensors to measure bridge responses toward external impacts such as loads, vibration, etc. It helps to assess the current condition of a structure and whether the structural components are safe. Bridge maintenance engineers use this technique to prioritize their maintenance schedule.

Typically, a structural health monitoring system consists of three main parts:

- A network of measurement sensors such as accelerometers, crack meters, load cells, etc.

- Data acquisition and transmission systems

- Monitoring and evaluation software

The structural health monitoring process may include continuous structural monitoring of structures over a long period. Therefore sensors used for structural health monitoring applications must be able to operate reliably over the period without needing replacement. There is also a challenge of data collection, storage and display in real-time to ensure that anomalies can be detected in real-time without delay.

Generally speaking, a well-designed structural health monitoring system can:

- Proactively monitor structural performance under operating and environmental changes

- Extending the bridge’s remaining lifespan by lowering failures brought on via early identification

- Real-time results can be used to optimise inspection budgets.

- Reduce lifecycle and dispensable maintenance expenditures.

- Boost public safety and structural integrity confidence

- Eliminate shutdown

The sensors used for Structural health monitoring applications must be able to continuously transmit data reliably to the interfaced measurement systems to enable round-the-clock monitoring of various bridge structure components, depending on where they are installed. When an anomaly is detected, engineers can focus on that area to identify whether the results are due to damage, instability or simply noises. An automated alarming systems can also be set up to notify bridge owners and operators of the results.

Check out the below video on how sensors are used for crack monitoring on bridges.

Practical Challenges

Monitoring the structural health of the bridge gives technicians, designers and inspection specialists information regarding the types of structural damage.

The challenge in establishing reliable structural health monitoring systems is the cohesiveness of the entire system to interface and communicate with each other. Monitoring large structures, such as bridges, buildings or dams, requires an enormous quantity of sensors installed at the right place to obtain the correct data. Collecting data from all these sensors will be challenging without incurring significant costs in buying the required data acquisition systems.

Sensors generally come with pre-attached cables. It is usually advised to minimise the cable length to minimize measurement noises and avoid loss of signals. When the wired sensors are used for monitoring large structures, there will be a high degree of complexity in laying out the cables safely without interfering with other aspects of the building. There may also be the possibility of using multiple data acquisition systems at numerous locations to collect the measurement signals from all the sensors.

Wireless sensors may offer practical yet cost-effective solutions for structural health monitoring applications. The cost associated with cable layout will be nulled and there is no need for long hours of labours needed for installation due to its simplicity.

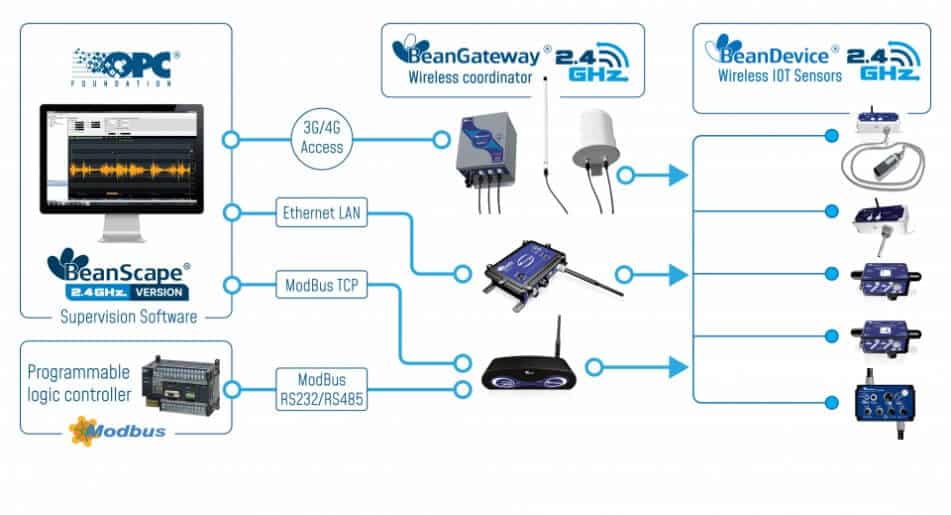

The Beanair wireless sensors and data acquisition systems have been used worldwide for structural health monitoring of bridges and dams. Any sensors can be connected to the gateway and communication systems as long as they are within the wireless line of sight, typically between 100-500m depending on the technology used. The Beanair wireless sensor systems also offer ultra-low power sensors for long periods of operations and store and forward functions to avoid data loss in a wireless outage. The shock sensors can also be programmed only to activate when a certain threshold is triggered, which further saves the requirement for ample data storage.

Quantifiable Bridge Health Monitoring Solutions from Bestech Australia

Bestech Australia has supplied wireless sensors from Beanair for structural health monitoring solutions. We are experts in industrial test and measurement applications and our specialists ensure that you use the suitable types of sensors and systems to obtain the right data types. As a leading sensors company in Oceania, we supply products and provide you with technical advice and support to your applications.

The technical professionals at Bestech Australia can also assist you in streamlining the selection process and choosing the best sensor for your bridge health monitoring applications. We may also provide customized SHM sensor solutions specifically designed for your unique requirements.