Print head positioning using laser triangulation sensors

Precision is crucial when printing small details on materials such as glass and ceramics. When printing on such types of materials, it sometimes becomes difficult to ensure that the printer’s printhead is at the exact position as desired. Nevertheless, correct positioning of the print head is the basic requirement for obtaining high-quality prints — which means that optoNCDT 1420 laser triangulation sensors from Micro-Epsilon are a must-have. Micro-Epsilon’s laser triangulation sensors are widely used in diverse industries including the printing industry. optoNCDT 1420 laser triangulation sensor helps to position the print head at the right distance from the surface. It...

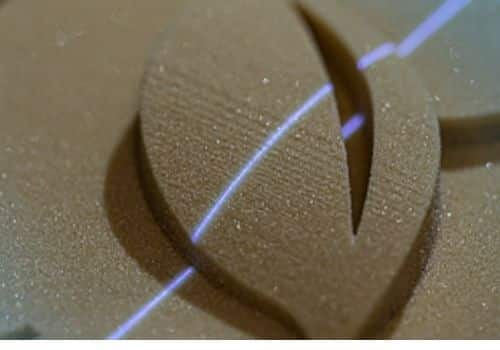

Distance control in 3D printing

Micro laser sintering is a method of additive manufacturing where a high-energy laser selectively melts and fuses fine metal powder into layers, based on a digital file. This is known as industrial 3D printing. During the process, a powder layer is applied and a squeegee is used for pulling off to the correct thickness. Then, the powder is melted in the component section followed by lowering the construction platform. To ensure that the squeegee is in the right position, the system uses four CSE05(01) capacitive sensors to detect the distance and tilt angle of the squeegee to the base. Moreover,...

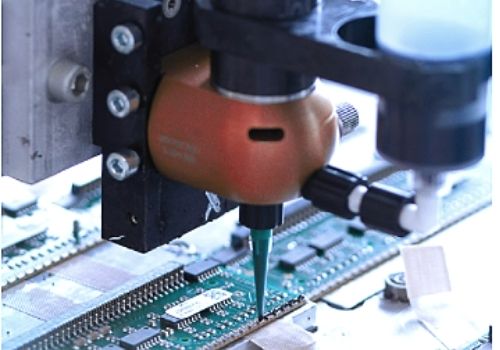

Glue bead measurement in dispensing systems

In the reflow soldering process, components are joined together by heating them to a temperature hot enough to melt solder, which creates a strong bond when cooled. Following each connection, a bead of glue is applied to some points to protect the circuit. When it comes to quality assurance, the thickness of the glue at the points on printed circuit boards that have been soldered is an important factor. Glue bead thickness must be measured in order to ensure no irregularities are present in the reflow soldering process. A reliable way to do this is by using a laser sensor....

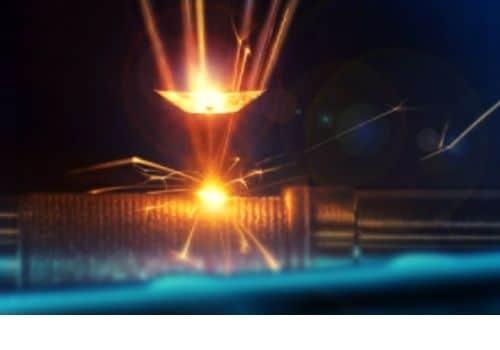

Deposition control of coatings

Laser cladding and laser deposition welding are two different methods of coating processes in additive manufacturing. Lasers can be adapted to the welding process in such a way that laser welds (or weld deposits) can be applied, effectively coating a material layer by layer. However, during the coating process, it is essential to monitor the weld deposition for ensuring uniform coating. To cater to this requirement, laser scanners from Micro-Epsilon are used that enable reliable and precise measurements. These profile scanners detect, measure, and evaluate profiles on different object surfaces without contact. Due to their compact size, it is easy...

CAD comparison of the printed component

3D printing, also known as additive manufacturing, is the construction of a three-dimensional object from a CAD model or digital 3D model. This technology is utilized in many industries such as aerospace and medical equipment. With ever more stringent quality standards and high-quality demands from customers, printed components are to be inspected to monitor production quality. This is because any deviation in the printed design can degrade the integrity of the final product. To implement a fast and effective way to analyze and trace deviations in prints, blue laser scanners are used that enable the comparison between printed components with...