Glue bead measurement in dispensing systems

In the reflow soldering process, components are joined together by heating them to a temperature hot enough to melt solder, which creates a strong bond when cooled. Following each connection, a bead of glue is applied to some points to protect the circuit. When it comes to quality assurance, the thickness of the glue at the points on printed circuit boards that have been soldered is an important factor.

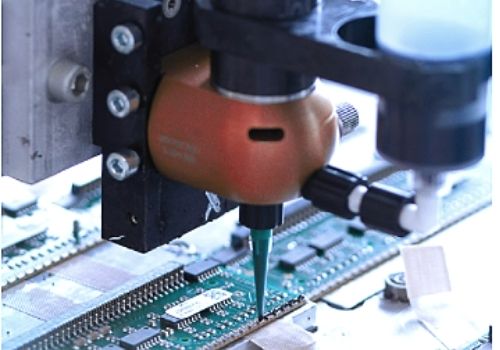

Glue bead thickness must be measured in order to ensure no irregularities are present in the reflow soldering process. A reliable way to do this is by using a laser sensor. optoNCDT 1420 is a smart laser triangulation displacement sensor that can be integrated into the system to precisely measure the thickness of the bead. With Active Surface Compensation (ASC), these sensors ensure stable measurement results regardless of changing surface colors or brightness.