Lloyd single column materials testers are cost effective, high quality machines with a force capacity of up to 5 kN. They are suitable for basic tensile, compression, bending, and shearing tests; as well as more complicated peeling, probing, friction, … tests. Double column units are also available with higher capacities of up to 150kN. How much maximum load you require will typically be the most important criterion, but not the only one.

Sample size and shape + grip dimensions, determine the test space required. Industrial or in-house testing standards typically specify the performance (speed) requirements of the machine. And then there are basic accuracy demands for the force and extension measurement systems. Materials testing machines from Lloyd Instruments guarantee the highest level of performance and capability for production testing, quality control, laboratory testing, research and education to provide expert materials testing solutions.

The powerful NEXYGENplus material testing software is developed and packaged with extensive automation features for routine QC testing, R&D and complex multi-stage testing with error-free, rapid and repeatable characters.

Highlights:

- Wide speed range (0.01-2032 mm/min)

- Exceptional load accuracy (better than ±0.5% down to 1% of load cell value)

- Large work surface accommodates samples

- Choice of 8 plug and play YLC Series load cells with different load ratings and resolutions

- Extensive range of grips, fixtures and extensometers

- Scalable operation from standalone to PC control

- Software integration with popular WINDOWS® software packages

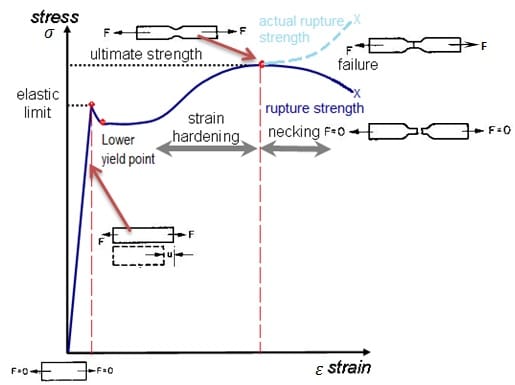

UTMs principally either compress or extend a test specimen, simultaneously measuring the force applied and the displacement moved. Together with the geometry of the test specimen this provides the often required classic stress-strain curve for that particular material. Effectively – by using tensile grips or compression platens – one end of the specimen is fixed to the machine while the other end is moved with respect to that. The movement is typically controlled to be a constant speed, but constant loading (force) rates are also possible with modern testers. A load cell built into the machine records the force and an extensometer is often used to measure the displacement.

As an example, the general stress-strain curve for a dumbbell shaped sample of a metal specimen is shown here:

There are two common types of UTMs, distinguished by their method of loading, electromechanical or servo hydraulic. Electromechanical machines allow very precise control during the test: an electric servo motor drive system is coupled to screwed rod arrangement that moves the loading cross-arm up or down. Hydraulic machines use servo controlled valves to regulate the flow of hydraulic fluid into and out of the loading piston. These heavily built machines tend to be more suited to high force testing of metals, cements, rocks and similar where a robust machine is essential.

There are two common types of UTMs, distinguished by their method of loading, electromechanical or servo hydraulic. Electromechanical machines allow very precise control during the test: an electric servo motor drive system is coupled to screwed rod arrangement that moves the loading cross-arm up or down. Hydraulic machines use servo controlled valves to regulate the flow of hydraulic fluid into and out of the loading piston. These heavily built machines tend to be more suited to high force testing of metals, cements, rocks and similar where a robust machine is essential.

There are two common types of UTMs, distinguished by their method of loading, electromechanical or servo hydraulic. Electromechanical machines allow very precise control during the test: an electric servo motor drive system is coupled to screwed rod arrangement that moves the loading cross-arm up or down. Hydraulic machines use servo controlled valves to regulate the flow of hydraulic fluid into and out of the loading piston. These heavily built machines tend to be more suited to high force testing of metals, cements, rocks and similar where a robust machine is essential.

There are two common types of UTMs, distinguished by their method of loading, electromechanical or servo hydraulic. Electromechanical machines allow very precise control during the test: an electric servo motor drive system is coupled to screwed rod arrangement that moves the loading cross-arm up or down. Hydraulic machines use servo controlled valves to regulate the flow of hydraulic fluid into and out of the loading piston. These heavily built machines tend to be more suited to high force testing of metals, cements, rocks and similar where a robust machine is essential. -

- UTMs can be utilized for various applications:

-

- – Automotive Components

-

- – Building Materials

-

- – Cosmetics

-

- – Micro-Electronic Components

-

- – Medical Devices

-

- – Packaging

-

- – Paper and Paperboard

-

- – Pharmaceuticals / Cosmetics

-

- – Plastics

-

- – Rubbers

-

- – Springs

-

- – Textiles