Bestech Australia provides comprehensive range of products for pressure, level, flow, integrated pressure-temperature measurements. Covering a wide variety of scopes and specifications, customers can easily find the right solutions for applications by choosing from our wide range of standard pressure measurement instruments as well as custom-designed or OEM applications.Highlights:

- Pressure capsules;

- Low cost models;

- Digital pressure gauges;

- Digital manometers;

- Pressure films;

- Fibre sensing for pressure measurement.

| Pressure range | 0 to 4000bar |

| Temperature range | -40°C to +260°C |

| Output options | 10mV to 300 mV |

| Process Connection | any male or female ISO, BSPT, NPT, etc. connection |

| IP protection rating | IP65, IP67, IP68 or others |

| Explosion proof option | Available |

| Custom / special design | Available |

| Media | Water, gas, flammable liquids, acids, alkaline, sewerage, chemicals, foods, etc. |

| Pressure Reference | Absolute, vented pressure, sealed gauge, differential |

| Frequency Response | up to 1MHz |

| Accuracy* | ±0.01%, ±0. 1%, ±0.25%, ±0.5% of FS or others |

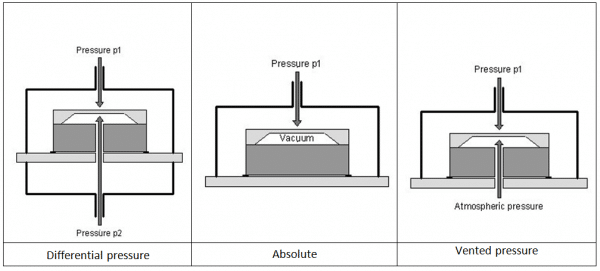

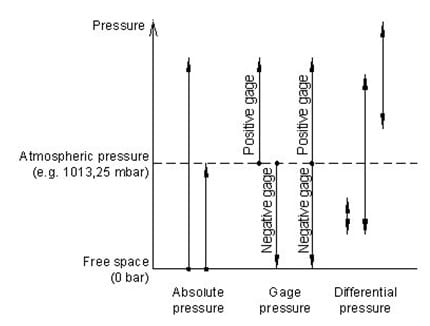

In the past decades, pressure transmitters have been improved significantly through different technologies and approaches that result in lower power consumption, suitability for different material, smaller size and weight, and fast response with high reliability, sensitivity, accuracy and repeatability. Below pictures and graph show different possible pressure references to adjust the pressure transmitter based on them.

to measure pressure. These approaches are mostly based on special requirement of customers and advantages of the technology executed. The most common sensing technologies used today are Force collector types, Piezo-resistive and Piezo-electric, Electromechanical Strain Gage, Variable Capacitance, Electromagnetic as well as optical fibre sensing. Force collector types are electronic pressure sensors using a force collector component, such as diaphragm, piston, bourdon tube, and/or bellows, to measure the strain caused by the applied force over an area, therefore, measure the pressure In respect of Piezo-resistive effect, Piezo-resistive material such as silicon, molecularly diffused onto a metal or micro-machined diaphragm, is used to detect strain generated by the applied pressure. Similar to strain gauge-based pressure transducers, Wheatstone bridge circuit is formed to maximize the output sensitivity of the sensor.

to measure pressure. These approaches are mostly based on special requirement of customers and advantages of the technology executed. The most common sensing technologies used today are Force collector types, Piezo-resistive and Piezo-electric, Electromechanical Strain Gage, Variable Capacitance, Electromagnetic as well as optical fibre sensing. Force collector types are electronic pressure sensors using a force collector component, such as diaphragm, piston, bourdon tube, and/or bellows, to measure the strain caused by the applied force over an area, therefore, measure the pressure In respect of Piezo-resistive effect, Piezo-resistive material such as silicon, molecularly diffused onto a metal or micro-machined diaphragm, is used to detect strain generated by the applied pressure. Similar to strain gauge-based pressure transducers, Wheatstone bridge circuit is formed to maximize the output sensitivity of the sensor.

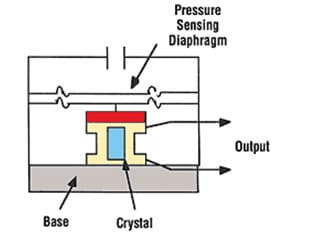

Piezoelectric materials are also used as sensing element due to their piezoelectric effect in response to applied mechanical stress.

Piezoelectric materials are also used as sensing element due to their piezoelectric effect in response to applied mechanical stress.

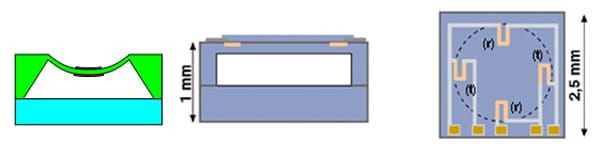

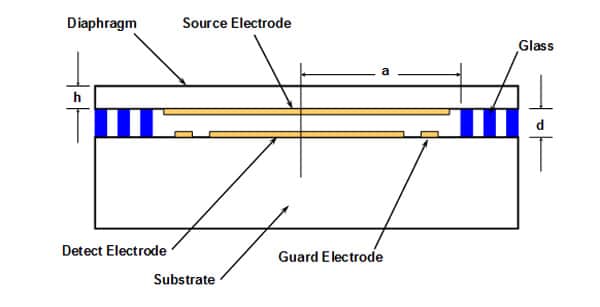

Capacitive pressure sensor uses a diaphragm and pressure cavity to create a variable capacitor to detect strain due to applied pressure. Common technologies use metal, ceramic, and silicon diaphragms. Generally, these technologies are most applied to low pressures (Absolute, Differential and Gauge).

Capacitive pressure sensor uses a diaphragm and pressure cavity to create a variable capacitor to detect strain due to applied pressure. Common technologies use metal, ceramic, and silicon diaphragms. Generally, these technologies are most applied to low pressures (Absolute, Differential and Gauge).

to measure pressure. These approaches are mostly based on special requirement of customers and advantages of the technology executed. The most common sensing technologies used today are Force collector types, Piezo-resistive and Piezo-electric, Electromechanical Strain Gage, Variable Capacitance, Electromagnetic as well as optical fibre sensing. Force collector types are electronic pressure sensors using a force collector component, such as diaphragm, piston, bourdon tube, and/or bellows, to measure the strain caused by the applied force over an area, therefore, measure the pressure In respect of Piezo-resistive effect, Piezo-resistive material such as silicon, molecularly diffused onto a metal or micro-machined diaphragm, is used to detect strain generated by the applied pressure. Similar to strain gauge-based pressure transducers, Wheatstone bridge circuit is formed to maximize the output sensitivity of the sensor.

to measure pressure. These approaches are mostly based on special requirement of customers and advantages of the technology executed. The most common sensing technologies used today are Force collector types, Piezo-resistive and Piezo-electric, Electromechanical Strain Gage, Variable Capacitance, Electromagnetic as well as optical fibre sensing. Force collector types are electronic pressure sensors using a force collector component, such as diaphragm, piston, bourdon tube, and/or bellows, to measure the strain caused by the applied force over an area, therefore, measure the pressure In respect of Piezo-resistive effect, Piezo-resistive material such as silicon, molecularly diffused onto a metal or micro-machined diaphragm, is used to detect strain generated by the applied pressure. Similar to strain gauge-based pressure transducers, Wheatstone bridge circuit is formed to maximize the output sensitivity of the sensor.

Piezoelectric materials are also used as sensing element due to their piezoelectric effect in response to applied mechanical stress.

Piezoelectric materials are also used as sensing element due to their piezoelectric effect in response to applied mechanical stress.

Capacitive pressure sensor uses a diaphragm and pressure cavity to create a variable capacitor to detect strain due to applied pressure. Common technologies use metal, ceramic, and silicon diaphragms. Generally, these technologies are most applied to low pressures (Absolute, Differential and Gauge).

Capacitive pressure sensor uses a diaphragm and pressure cavity to create a variable capacitor to detect strain due to applied pressure. Common technologies use metal, ceramic, and silicon diaphragms. Generally, these technologies are most applied to low pressures (Absolute, Differential and Gauge).

For more details, please CONTACT US with your application details.