“Eliminate waste and save money be detecting leakage in your food packaging process.”

The package leak testing equipment from Sealtick is designed to test the package integrity of food and pharmaceutical packaging. Seal integrity testing is crucial as part of a production process in the food and pharmaceutical industry to ensure that the contents are protected against environmental or foreign substances that may deteriorate or speed product decomposition.

Our innovative package leak testing equipment is non-destructive in nature, meaning that the tested packages can be directly returned to the production line. The devices detect leaks based on the vacuum decay principle which is generally an acceptable method for leak testing of non-porous, rigid and flexible packaging.

With the Sealtick leak testing devices, almost all types of packages can be leak tested, provided that the packages contain head-space of air or any gases. The contents should be dry as presence of moisture may mask leaks which may return an unreliable or inaccurate reading.

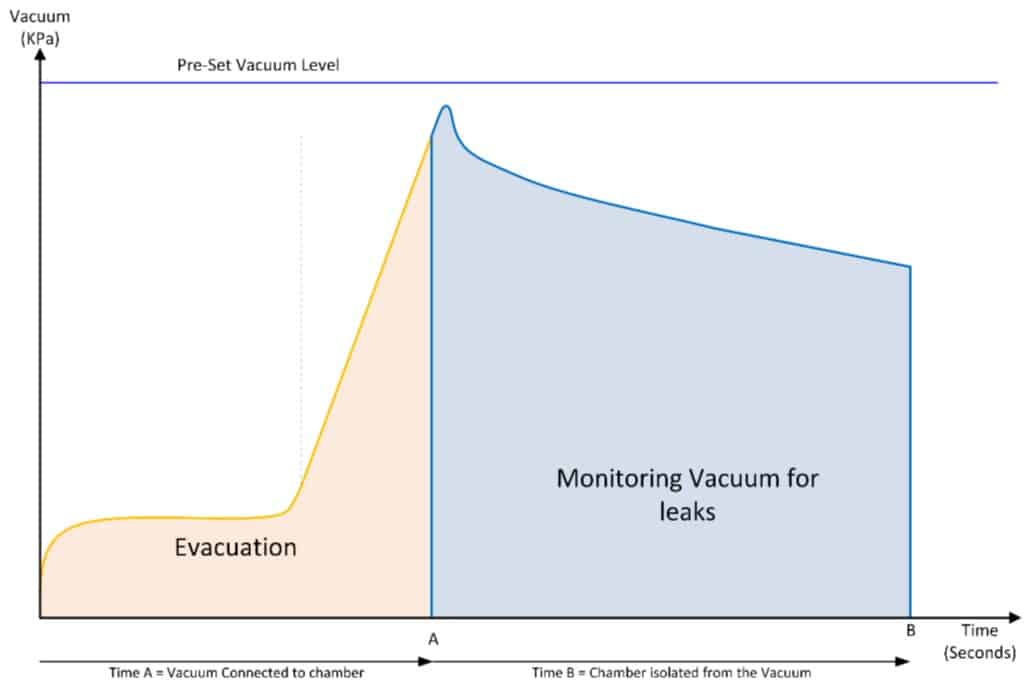

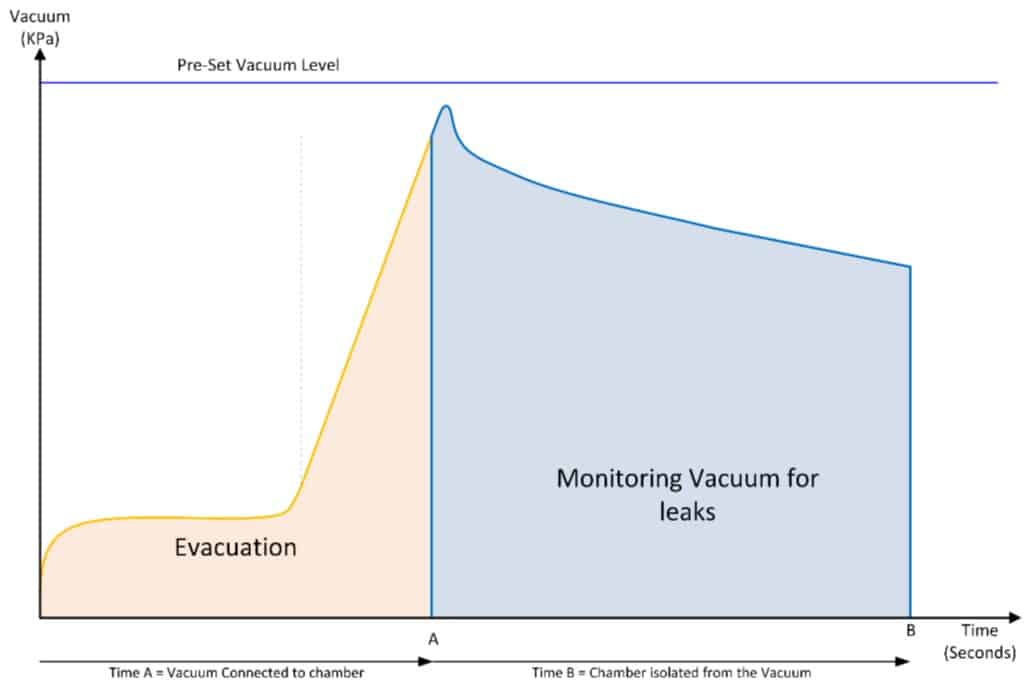

The tests can be completed in as little as 5-20 seconds and are easy to operate. The tests can be initiated by placing the test item in the test chamber which is evacuated to a preset vacuum level. The chamber is then isolated so that any leaks will allow a return of chamber pressure towards atmospheric pressure. The vacuum pressure is measured during this process and generate a pressure profile such as shown below. The time taken to reach the preset vacuum can be used to determine large leaks. Fine or small leaks are identified based on the rate of vacuum decay towards atmospheric pressure once the chamber is isolated.

“Eliminate waste and save money be detecting leakage in your food packaging process.”

The package leak testing equipment from Sealtick is designed to test the package integrity of food and pharmaceutical packaging. Seal integrity testing is crucial as part of a production process in the food and pharmaceutical industry to ensure that the contents are protected against environmental or foreign substances that may deteriorate or speed product decomposition.

Our innovative package leak testing equipment is non-destructive in nature, meaning that the tested packages can be directly returned to the production line. The devices detect leaks based on the vacuum decay principle which is generally an acceptable method for leak testing of non-porous, rigid and flexible packaging.

With the Sealtick leak testing devices, almost all types of packages can be leak tested, provided that the packages contain head-space of air or any gases. The contents should be dry as presence of moisture may mask leaks which may return an unreliable or inaccurate reading.

The tests can be completed in as little as 5-20 seconds and are easy to operate. The tests can be initiated by placing the test item in the test chamber which is evacuated to a preset vacuum level. The chamber is then isolated so that any leaks will allow a return of chamber pressure towards atmospheric pressure. The vacuum pressure is measured during this process and generate a pressure profile such as shown below. The time taken to reach the preset vacuum can be used to determine large leaks. Fine or small leaks are identified based on the rate of vacuum decay towards atmospheric pressure once the chamber is isolated.